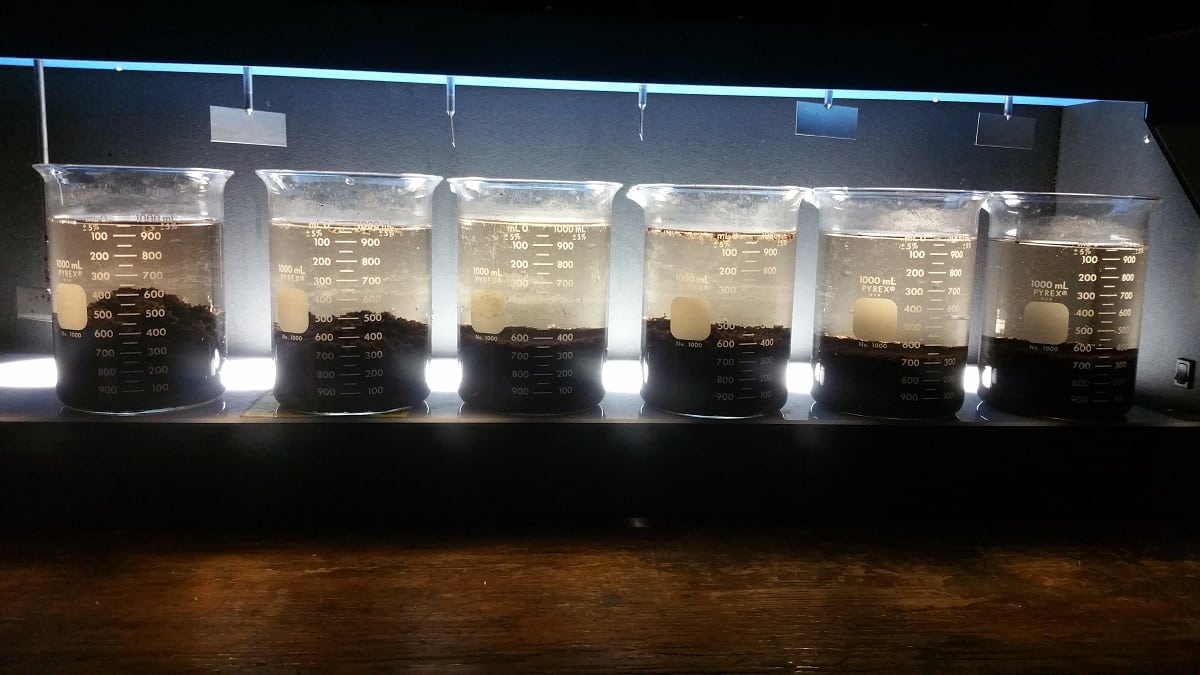

Jar Testing

There are two no-cost options to have Bond evaluate your current wastewater treatment chemistry.

Option #1 is to have a Bond Water Representative come to your site and perform a no-cost site evaluation along with jar testing.

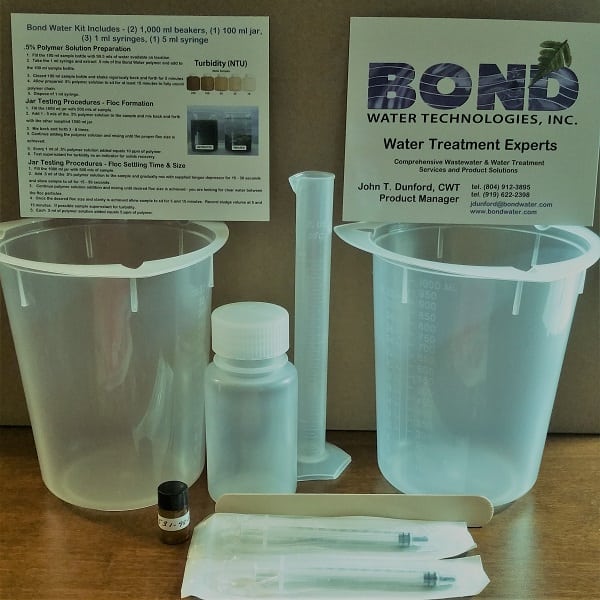

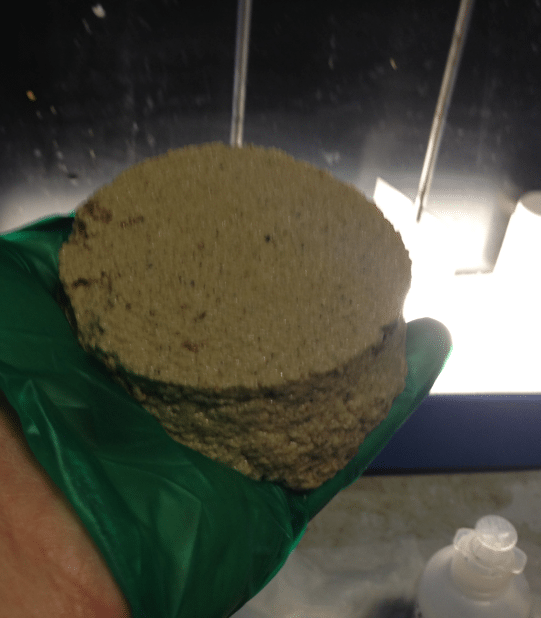

Option #2 is shown in the first image below. We will ship you a no-cost test kit to evaluate your treatment at your leisure.