Sustainability Spotlight for Wastewater Landfill Sludge Reduction Project

Project Summary:

Bond Water Technologies was approached by a large national food processing plant to help manage their wastewater sludge reduction plan. The plant estimates a daily sludge haul of 3,000 gallons (3% solids) from its wastewater treatment process, incurring $500K in sludge hauling costs alone in 2023. The project aims to reduce daily sludge hauls, landfill additions, and associated carbon emissions from trucking transportation.

Project Implementation Steps:

- Evaluation of Current Process and Investigation:

- Assessed the existing process, which includes an EQ tank (250K) feeding centrifuges before chemical treatment to remove solids, with an average 35% solids rendered into feed for livestock.

- Initiated an investigation into the possibility of sending sludge generated from the treatment process to the centrifuges for removal via rendering, aiming to eliminate landfill disposal and reduce transportation mileage.

- Evaluation of Chemical Treatments:

- Identified GRAS approved chemistries for coagulant and polymer treatment to enable rendering of treated sludge.

- Development of Chemical Feed System:

- Created an automatic chemical feed system to adjust with varying strengths of incoming wastewater streams, preventing under and overfeeding of chemistry.

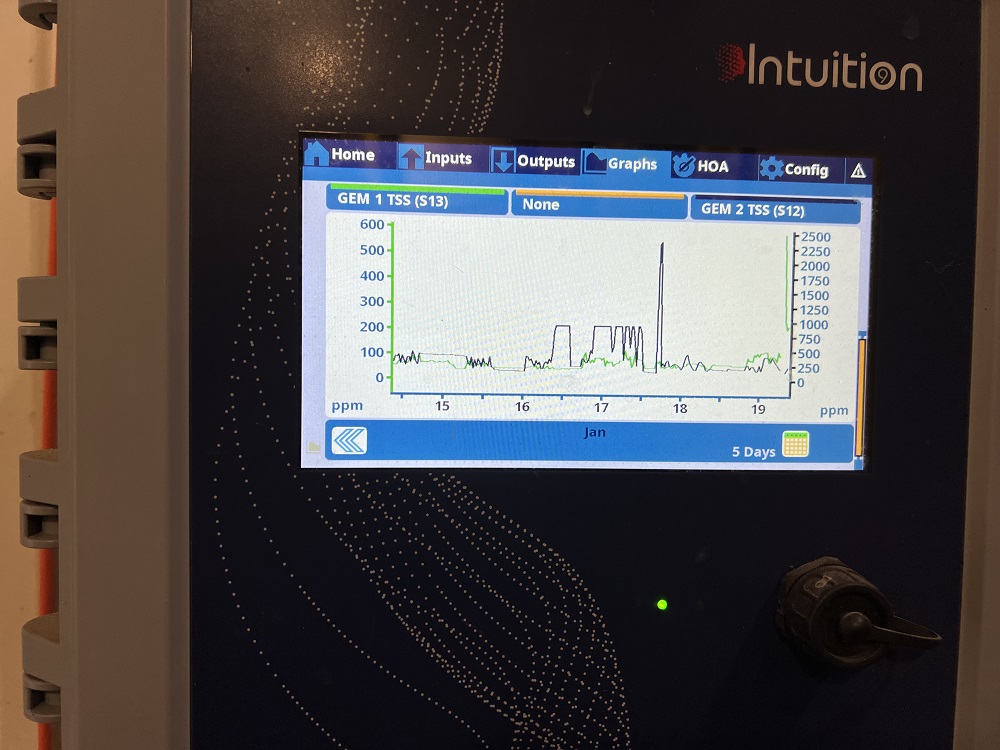

- Utilized a TSS monitoring feed system to base feed all chemistry at the lowest end of the feed range, automatically adjusting as incoming TSS increased.

- Installation of Sludge Recirculation Pump:

- Installed a sludge recirculation pump and feed pump to mix the sludge tank and provide a consistent percent solids feed to the centrifuges.

- Automatic Adjustment of Polymer Feed:

- Addressed variations in percent solids from the sludge tank due to decanting by automatically adjusting polymer feed for thickening.

- Added an additional TSS probe to the centrate tank of the centrifuges connected with the variable-speed polymer feed system to automatically adjust polymer feed to varying conditions and target a solids capture rate.

Project Outcomes:

- The facility earned “The Most Improved Industrial Pre-Treatment Award”.

- Successfully implemented feeding sludge to the centrifuges, resulting in significant achievements:

- Reduced sludge hauls from daily to monthly, with an estimated monthly landfill reduction of 87,000 gallons.

- Projected monthly mileage reduction in trucking transportation of 3,000 miles, leading to an associated CO2 reduction of 5,610 pounds per month.

References:

- Greenhouse Gas Emissions from a Typical Passenger Vehicle: Questions and Answers – Fact Sheet (EPA-420-F-23-014, June 2023)