Reduce Your Wastewater Costs!

We are often asked to help evaluate and reduce a plants wastewater expenses. Whether they have clarifiers, generic settling tanks or dissolved air flotation systems, the common thread seems to be they are trying to get the water as “clean” as possible before sending it down the drain.

The first thing we ask a prospect is how do they quantify if the treated water is OK to send down the drain. Typically we are told “we like to see clear water, almost like you drink it”. While this is fantastic, it is also a tremendous waste of your wastewater treatment chemicals. First, the POTW sets treatment levels – a top number not to exceed (NOV – Notice of Violation). These numbers are set based on what the POTW’s treatment facility can handle. Second, the POTW will have surcharges on certain things in your effluent. So not only are you paying to treat your wastewater at your facility, but you are also paying to treat your wastewater at their facility. Why in the heck would you want to spend a lot of money on specialty treatment chemicals to have your effluent so clean that you could “almost drink it” and on the back side you will still be surcharged? The key is to find a happy medium by producing an effluent that meets your permit and balances expenditures on your pretreatment chemicals and surcharges. OK, sounds great…..how do you do this?

Common permit limits will be pH, BOD/COD, FOG and TSS. Typically, these all work hand in hand. If one of these is elevated, they all will be elevated (assuming that the BOD/COD is insoluble). First, your specialty chemical company needs to work with you to develop a few KPI’s (Key Performance Indicators) and provide monthly service visits (minimum) to verify your chemical feed rates by jar testing to ensure program success. Typically, pH will be critical to the performance of your coagulant/polymer along with a range in your effluent that is on your permit. So for pH you should have a KPI for the treatment process and a KPI for the effluent. The next KPI is measuring turbidity in your effluent and correlating to your TSS that is measured by the POTW. When the POTW has the composite sampler in your effluent, just ask them for a 10 ml sample so that you can test the turbidity and then you can correlate the turbidity with the TSS. Measuring pH and turbidity and a weekly control calibration will take only a few minutes and should be documented by your supplier. Bond Water has an on-line reporting system that allows the customer to input their readings along with additional notes that get emailed to various contacts within the account. This allows us to give additional oversight as a consultant and advise between service visits.

Common permit limits will be pH, BOD/COD, FOG and TSS. Typically, these all work hand in hand. If one of these is elevated, they all will be elevated (assuming that the BOD/COD is insoluble). First, your specialty chemical company needs to work with you to develop a few KPI’s (Key Performance Indicators) and provide monthly service visits (minimum) to verify your chemical feed rates by jar testing to ensure program success. Typically, pH will be critical to the performance of your coagulant/polymer along with a range in your effluent that is on your permit. So for pH you should have a KPI for the treatment process and a KPI for the effluent. The next KPI is measuring turbidity in your effluent and correlating to your TSS that is measured by the POTW. When the POTW has the composite sampler in your effluent, just ask them for a 10 ml sample so that you can test the turbidity and then you can correlate the turbidity with the TSS. Measuring pH and turbidity and a weekly control calibration will take only a few minutes and should be documented by your supplier. Bond Water has an on-line reporting system that allows the customer to input their readings along with additional notes that get emailed to various contacts within the account. This allows us to give additional oversight as a consultant and advise between service visits.

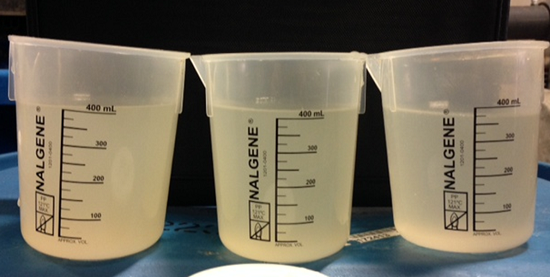

Here’s an example of jar testing and using KPIs. The following is a set of jar tests with various chemical dosages along with daily costs. We are using turbidity as the KPI with an upper limit of 100 NTUs.

Going from left to right, jar #1 has a turbidity of 105 NTUs, jar #2 has a turbidity of 75 NTUs and jar #3 has a turbidity of 38 NTUs. Also, the cost to treat per day is jar #1 at $32/day, jar #2 at $45/day, and jar #3 at $65/day. Jar #2 puts you under your KPI and will save you $7,300 per year in chemical costs alone. Not to mention it is less sludge disposal, another high cost for your treatment operation.

The key is working closely with your supplier to consistently balance the KPI’s so you can both operate within your permit but in a range that makes sense for your budget.

Are you getting the service you deserve? Do you have cost concerns or maybe question how your program is balanced? Schedule a free evaluation from Bond by clicking the button below.